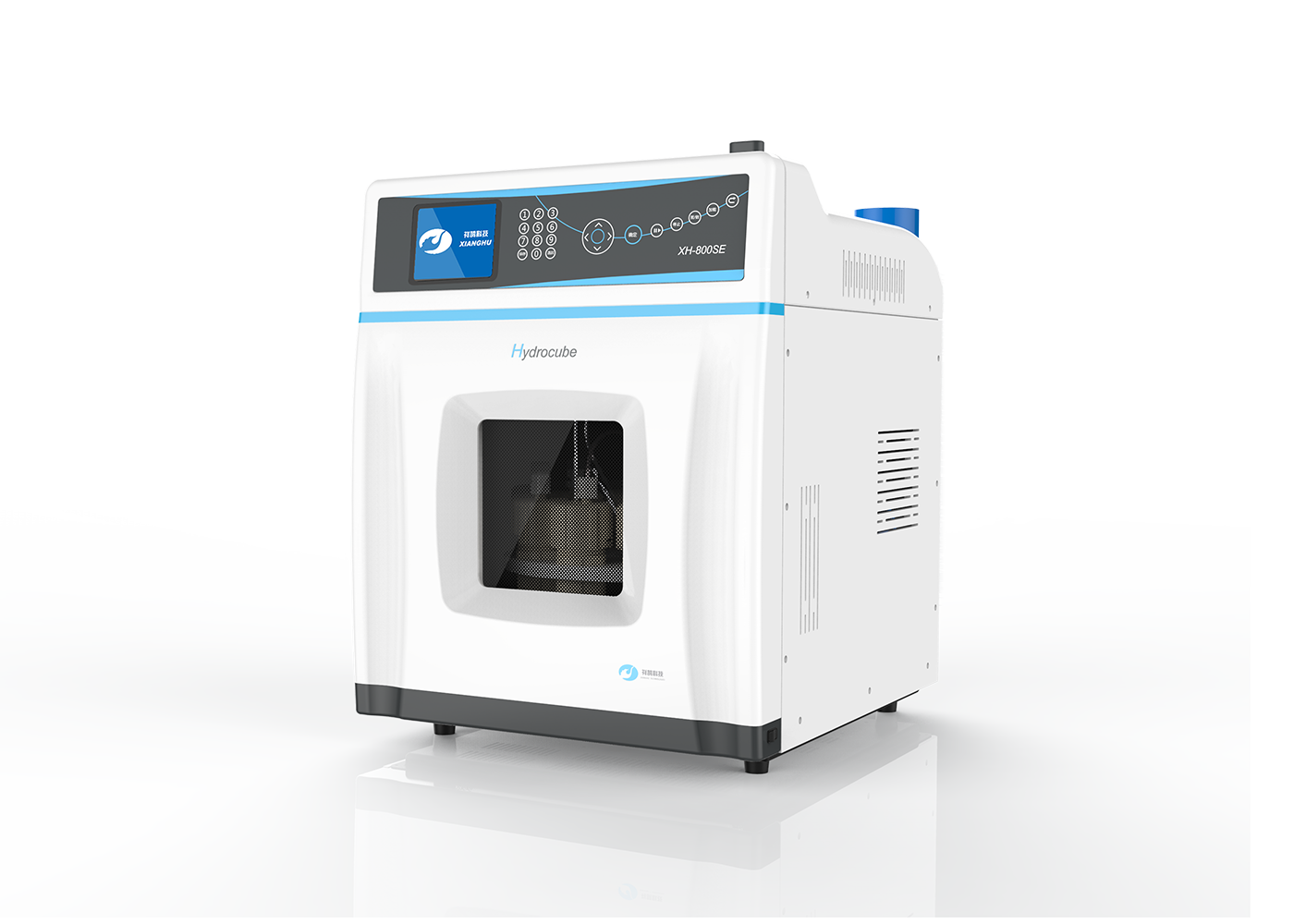

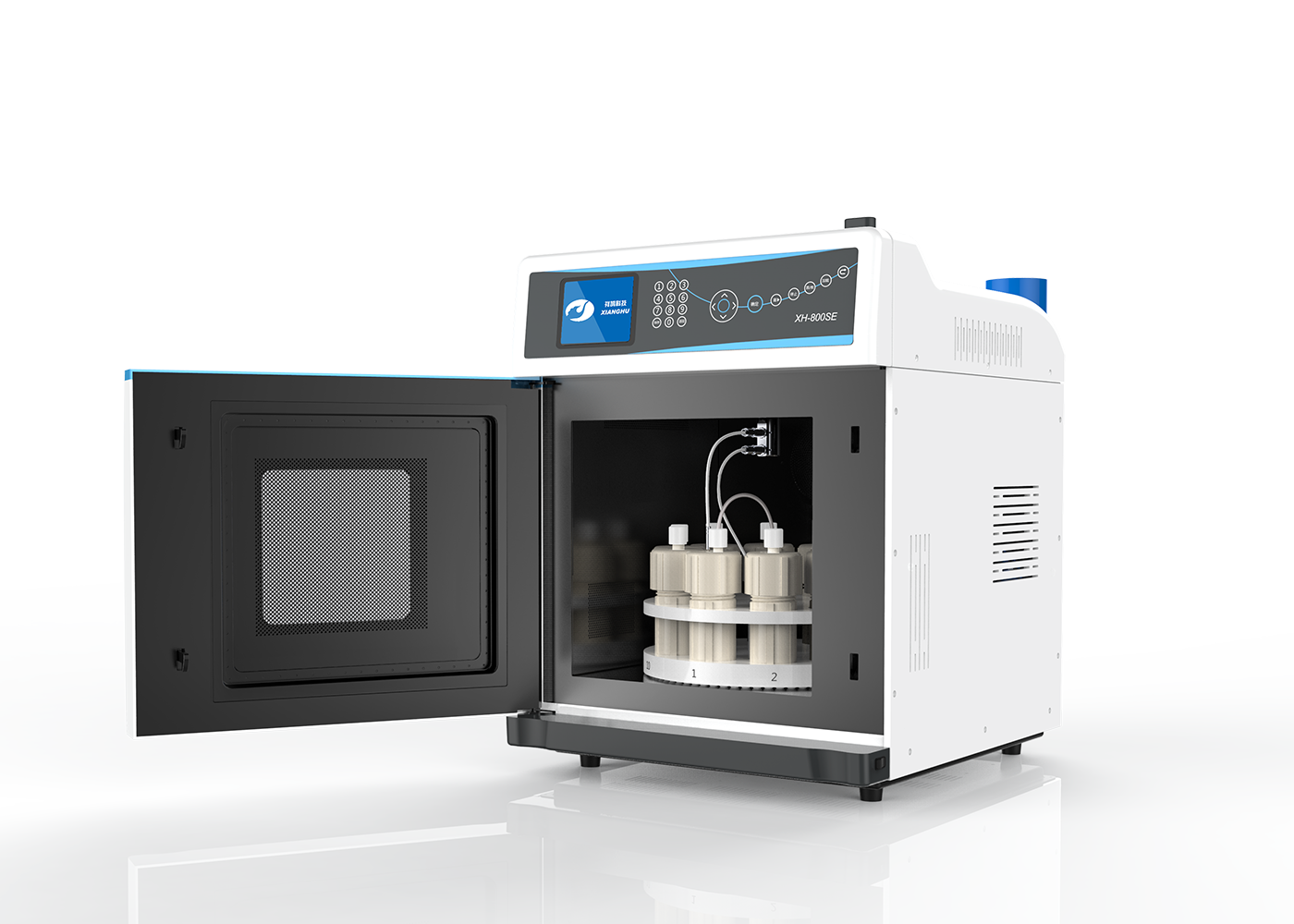

XH-800SE MW Hydrothermal Synthesis Instrument

Hydrocube

Instrument functions:

Experimental function:

Experimental condition:

Experimental purpose: